Graphite, a versatile material, is widely used in various industries such as semiconductors and new - energy batteries. However, during the graphite processing, dust pollution is a common and serious problem. This dust can have a significant impact on the precision and lifespan of CNC machine tools.

The dust generated in graphite processing can cause various damages. For example, it can erode the guide rails, lead screws, and electrical systems of the machine tools. When dust invades the guide rails, it can increase the friction between the moving parts, resulting in a decrease in the smoothness of movement. According to industry data, in traditional dry - processing environments, the positioning error of machine tools can reach up to 0.05mm due to dust on the guide rails. This not only affects the dimensional accuracy of the workpiece but also shortens the service life of the guide rails.

In the case of lead screws, dust can cause abrasion, leading to a loss of transmission accuracy. A real - world example is a graphite processing factory where, without proper dust control, the lead screws of their machine tools needed to be replaced every 6 months on average. The dust also poses a threat to the electrical systems. It can accumulate on circuit boards and electronic components, causing short - circuits and malfunctions, which may lead to unexpected machine downtime.

Dust mainly invades machine tools through three main paths: guide rails, lead screws, and electrical systems. The open structure of traditional machine tools makes them vulnerable to dust intrusion. For instance, the gaps around the guide rails and lead screws are easy entry points for dust particles. Once inside, these particles can cause long - term damage.

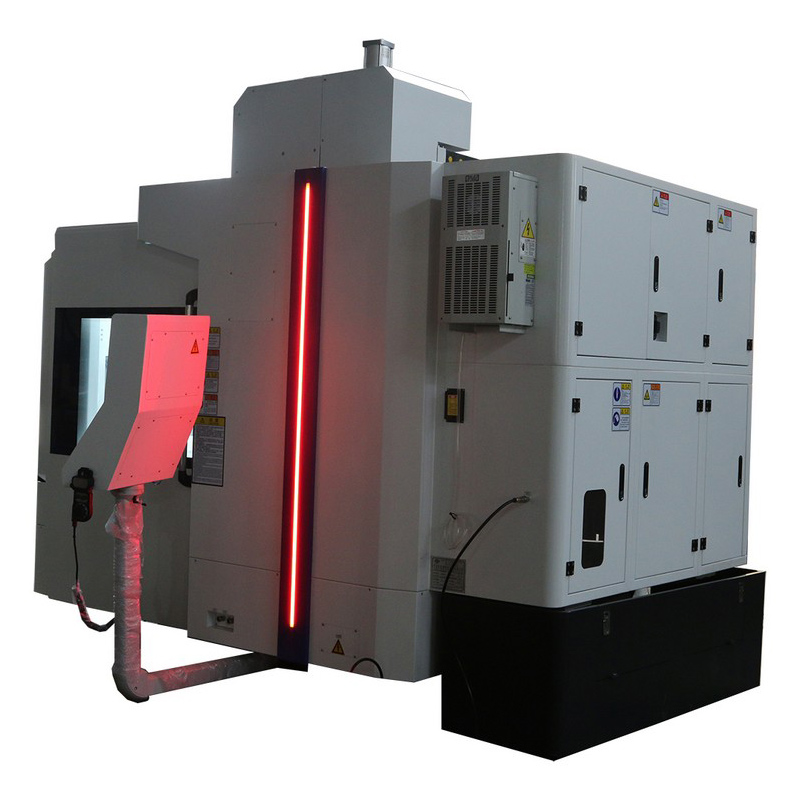

To address this industry pain point, the DC6060G wet graphite machining center adopts a dual - protection solution of a full - sealed cover and a wet - flushing system. The full - sealed structure prevents dust from entering the machine tool from the outside. The wet - flushing system, on the other hand, uses water to clean the internal components of the machine tool, removing dust particles in a timely manner.

The principle of the wet - flushing system is based on the fact that water can effectively adsorb dust particles. By spraying water on the guide rails, lead screws, and other key components, the dust is washed away and collected in a special container. The combination of the full - sealed cover and the wet - flushing system creates a synergistic effect, significantly improving the dust - control ability of the machine tool.

| Indicators | Traditional Dry Processing | DC6060G Wet Graphite Machining Center |

|---|---|---|

| Cleanliness | Low. Dust accumulates on machine surfaces and internal components. | High. The wet - flushing system keeps the internal environment clean. |

| Consistency | Poor. Dimensional accuracy fluctuates due to dust - related issues. | Good. The positioning error can be reduced to within 0.01mm. |

| Maintenance Cost | High. Frequent replacement of components due to dust damage. | Low. The long - term stability reduces the need for frequent part replacement. |

The DC6060G wet graphite machining center has been widely used in the semiconductor and new - energy battery industries. In semiconductor manufacturing, where high - precision and high - cleanliness requirements are crucial, this machine tool can ensure the stability of the production process. In the new - energy battery field, it helps to improve the quality and consistency of battery components.

Many customers have provided positive feedback. One semiconductor manufacturer reported that after using the DC6060G, the rejection rate of their products decreased by 30% due to improved machining accuracy. Another new - energy battery company said that the maintenance cost of their machine tools was reduced by 40%.

If you are looking for a reliable solution to improve the precision and stability of your graphite processing, don't miss out on the DC6060G wet graphite machining center. Click here to learn more about our high - efficiency dust - control solutions and take your graphite processing to the next level!