In the field of manufacturing, the efficiency of rough machining large parts is a crucial factor affecting production cycles and costs. The FH1890L large-travel heavy-duty vertical machining center newly launched by Ningbo Kaibo CNC Machinery Co., Ltd. has attracted much attention for its excellent performance in this regard. This article will conduct an in - depth analysis of its design features and the impact on rough machining performance.

The bed casting process of the FH1890L is one of the key factors contributing to its high rigidity. Through advanced casting technology, the bed has a stable structure that can effectively resist deformation during high - speed and heavy - load machining. For example, the use of high - strength cast iron materials and optimized rib layout can increase the overall stiffness of the bed by about 30% compared with traditional designs. This improvement allows the machine tool to maintain better stability during rough machining of large parts, reducing vibration and improving machining accuracy.

Moreover, the high - precision guide rails used in the FH1890L also play an important role. Linear guide rails with high precision and low friction coefficient are adopted, which can ensure smooth movement of the worktable and spindle. In actual production, the use of these guide rails can increase the positioning accuracy of the machine tool to within ±0.005mm, and the repeat positioning accuracy to within ±0.003mm. This high - precision movement ensures that the machine tool can perform accurate rough machining operations on large parts, improving the surface quality of the workpiece.

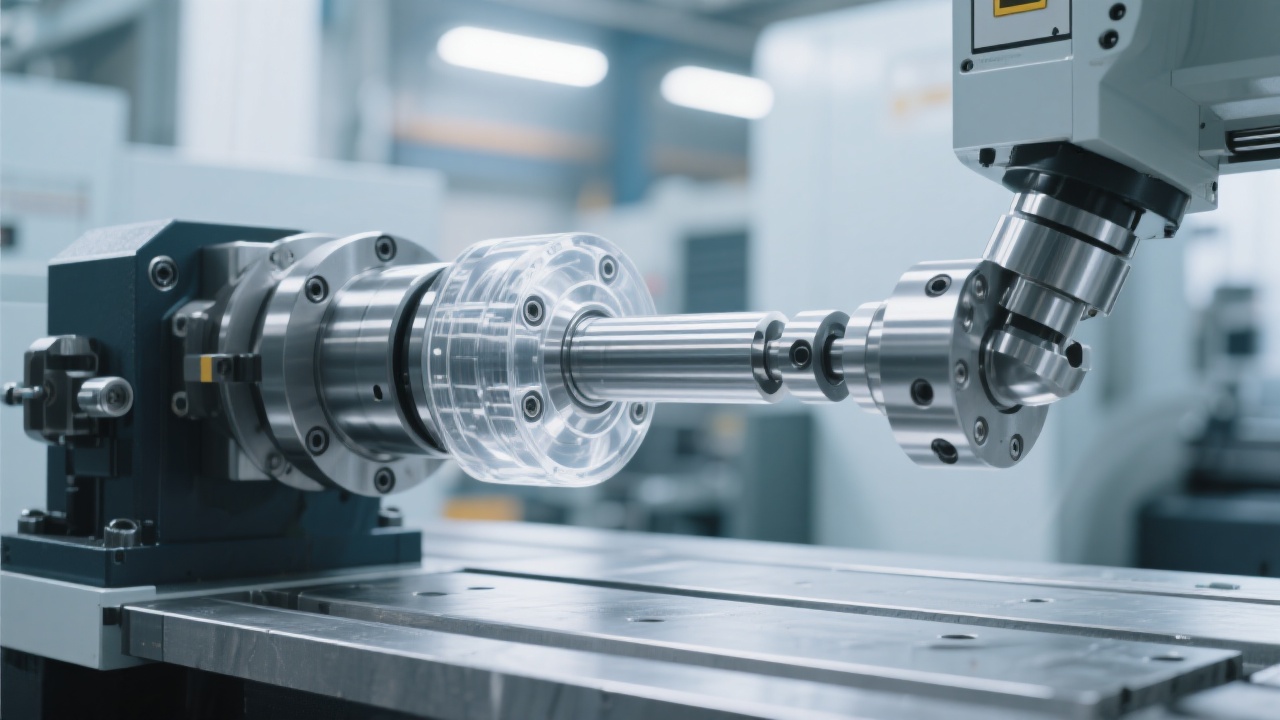

The spindle is the core component of the machining center, and its power and torque directly affect the rough machining performance. The FH1890L is equipped with a high - power spindle with a power of up to 30kW. This high - power spindle can provide sufficient cutting force during rough machining, allowing the machine tool to quickly remove a large amount of material from the workpiece. For instance, when machining large automotive parts, the high - power spindle can increase the material removal rate by about 40% compared with spindles of lower power.

In addition to power, the spindle torque also has a significant impact on rough machining. The FH1890L spindle can provide a maximum torque of 500 N·m at low speeds. This high torque enables the machine tool to perform heavy - cutting operations on hard materials, such as high - strength steel and cast iron. In practical applications, the high - torque spindle can reduce the cutting time of large parts by about 30%, effectively improving production efficiency.

The FH1890L is equipped with a Mitsubishi controller, which has excellent operation response and stability. The Mitsubishi controller uses advanced control algorithms and high - speed processors, which can quickly process a large number of control signals. For example, in the process of high - speed machining, the controller can adjust the cutting parameters in real - time according to the machining state, ensuring the stability of the machining process. The response time of the controller is less than 100ms, which can effectively avoid machining errors caused by delayed response.

At the same time, the Mitsubishi controller also has high stability. It can work stably in a variety of harsh industrial environments, with a failure rate of less than 1% within one year of continuous operation. This high stability ensures that the machine tool can operate continuously for a long time, reducing the downtime caused by controller failures and improving production efficiency.

Optimizing machining parameters is an important means to improve the rough machining efficiency of the FH1890L. By adjusting cutting speed, feed rate, and tool selection, the machining efficiency can be significantly improved. For example, when machining aluminum alloy parts, increasing the cutting speed from 500m/min to 800m/min and adjusting the feed rate from 0.1mm/r to 0.2mm/r can increase the material removal rate by about 50%.

The FH1890L is also equipped with a variety of multifunctional accessories, such as right - angle heads and universal heads. These accessories can expand the machining range of the machine tool and enable it to perform machining operations on complex - shaped workpieces. For example, using a right - angle head, the machine tool can perform side - facing and drilling operations on large parts, which was difficult to achieve with a single - spindle machining center. In practical production, the use of these multifunctional accessories can increase the machining flexibility of the machine tool by about 60%.

A manufacturing company in the automotive industry used the FH1890L to process large engine blocks. Before using the FH1890L, the rough machining process of each engine block took about 2 hours, and the rejection rate was about 5%. After using the FH1890L, through parameter optimization and the use of multifunctional accessories, the rough machining time of each engine block was reduced to 1.2 hours, and the rejection rate was reduced to 1%. This shows that the FH1890L can effectively improve production efficiency and product quality.

In conclusion, the FH1890L large - travel heavy - duty vertical machining center has significant advantages in improving the rough machining efficiency of large parts through its rigid structure design, high - power spindle, stable controller, and multifunctional accessories. If you are looking for a machining center that can improve production efficiency and reduce costs, the FH1890L is definitely a worthy choice. Click here to learn more about the FH1890L and how it can transform your manufacturing process!