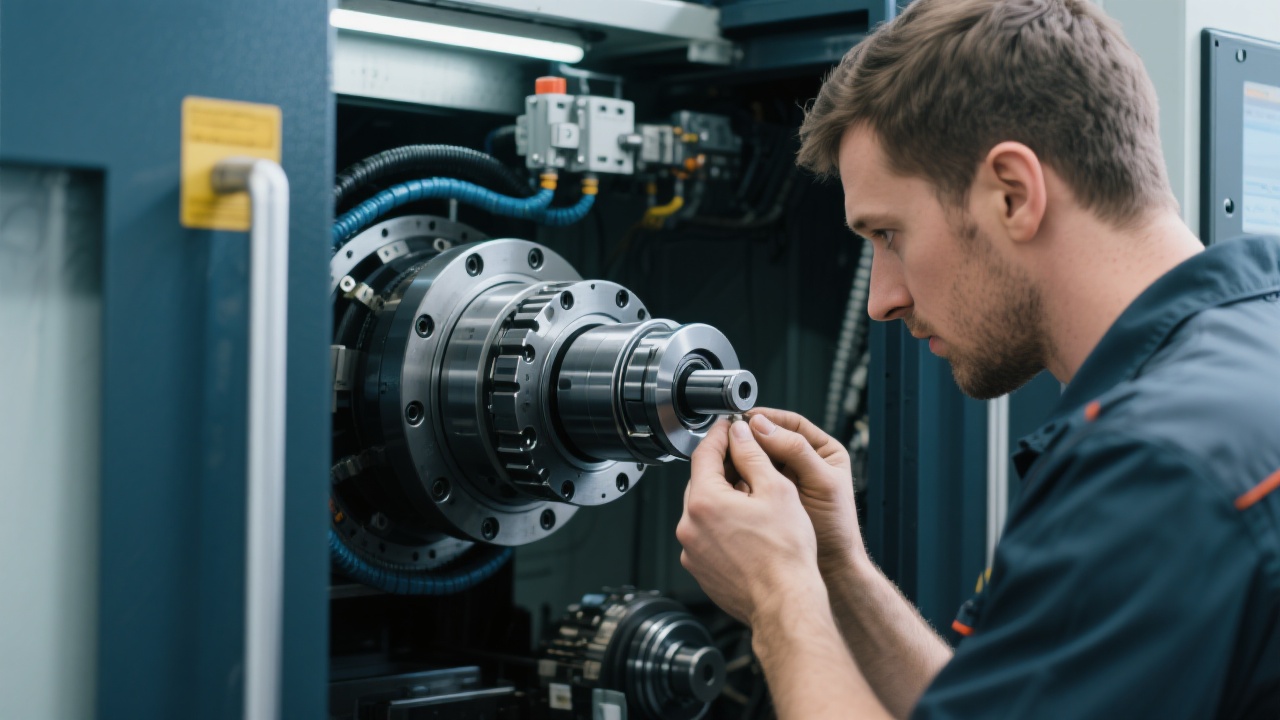

In the automotive manufacturing industry, the efficiency of rough machining large parts, such as automotive hubs, is crucial for enhancing overall production capacity and competitiveness. The FH1890L large - stroke vertical machining center recently launched by Ningbo Kaibo CNC Machinery Co., Ltd. has emerged as a game - changer in this field. Let's delve into its features and real - world applications.

The FH1890L features a robust structural design. Its heavy - duty base and column are made of high - quality cast iron, which provides excellent stability and vibration absorption. The advanced power system, equipped with a high - torque spindle motor, can reach a maximum speed of 6000 rpm, delivering sufficient power for rough machining of large automotive parts. For example, when machining a large - sized automotive hub, the high - power spindle can quickly remove excess material, significantly improving the rough machining efficiency.

The FH1890L is equipped with an advanced Mitsubishi controller, which is the key to its precise and stable operation. The controller has a high - speed processing capability, with a response time of less than 0.1 seconds, ensuring real - time control of the machine tool. It can accurately control the movement of the spindle and axes, maintaining high - precision machining even during high - speed operation. In a long - term continuous machining test, the machining accuracy deviation of the FH1890L controlled by the Mitsubishi controller was less than ±0.01mm, which is far superior to many similar products in the market. This advanced Mitsubishi controller guarantees precise and stable production, which is essential for high - quality automotive part machining.

To further improve the efficiency of large - part rough machining, optimizing the machining process parameters is essential. By adjusting parameters such as cutting speed, feed rate, and cutting depth, the machining efficiency can be significantly enhanced. For instance, when machining automotive hubs, increasing the cutting speed from 300 m/min to 400 m/min and adjusting the feed rate from 0.2 mm/r to 0.3 mm/r can increase the material removal rate by about 30%, effectively shortening the machining cycle.

The FH1890L can be equipped with right - angle heads and universal heads, which greatly expand its machining capabilities. The right - angle head allows the machine tool to perform side - facing and perpendicular machining operations, which is very useful for machining complex - shaped automotive parts. The universal head can rotate in multiple directions, enabling the machining of parts with irregular surfaces. In a practical application, a complex - shaped automotive hub was machined. By using the right - angle head and universal head, the number of clamping times was reduced from 5 times to 2 times, and the machining efficiency was improved by about 25%.

Let's take a look at a real - world case of an automotive hub manufacturer. Before using the FH1890L, the company used a traditional machining center for hub rough machining. The average machining cycle for each hub was about 60 minutes, and the production capacity was limited. After introducing the FH1890L, with its high - power spindle, advanced controller, and optimized machining parameters, the average machining cycle was reduced to 42 minutes, achieving a 30% improvement in machining efficiency. The following table shows the comparison:

| Machining Equipment | Average Machining Cycle per Hub (minutes) | Production Capacity per Day (pieces) |

|---|---|---|

| Traditional Machining Center | 60 | 80 |

| FH1890L | 42 | 114 |

This significant improvement in efficiency not only increased the company's production capacity but also reduced the production cost per unit, enhancing its market competitiveness.

In conclusion, the FH1890L large - stroke vertical machining center, with its advanced technical features, optimized machining processes, and the application of multifunctional accessories, can effectively improve the rough machining efficiency of large automotive parts, shorten the machining cycle, and bring tangible economic benefits to manufacturing enterprises. If you are also looking for a solution to improve your automotive part machining efficiency, click here to learn more about the FH1890L.