As a technical leader or procurement manager in the iron mold manufacturing industry, you're likely all too familiar with the challenges of selecting the right CNC milling machine. Incorrect choices often lead to low machining accuracy, poor efficiency, and high rework rates. In this application tutorial, we'll delve into the key aspects of selecting CNC milling machines for processing gray cast iron and ductile cast iron, leveraging Kaibo CNC's 25 - year industry experience.

Let's start with real - world scenarios. High rework rates are a common headache in iron mold production. For example, a company once had a rework rate of up to 30% due to improper machine selection. This not only increases production costs but also extends the production cycle. Another issue is the short lifespan of equipment. Some machines may break down frequently within 2 - 3 years, which disrupts the production schedule. These pain points highlight the importance of making the right choice when it comes to CNC milling machines.

There are several key technical points to consider. First, let's talk about positioning accuracy and repeat positioning accuracy. Positioning accuracy refers to how accurately the machine can move to a specified position, while repeat positioning accuracy indicates the consistency of the machine's movement to the same position. For high - precision iron mold production, a positioning accuracy of ±0.01mm and a repeat positioning accuracy of ±0.005mm are often required.

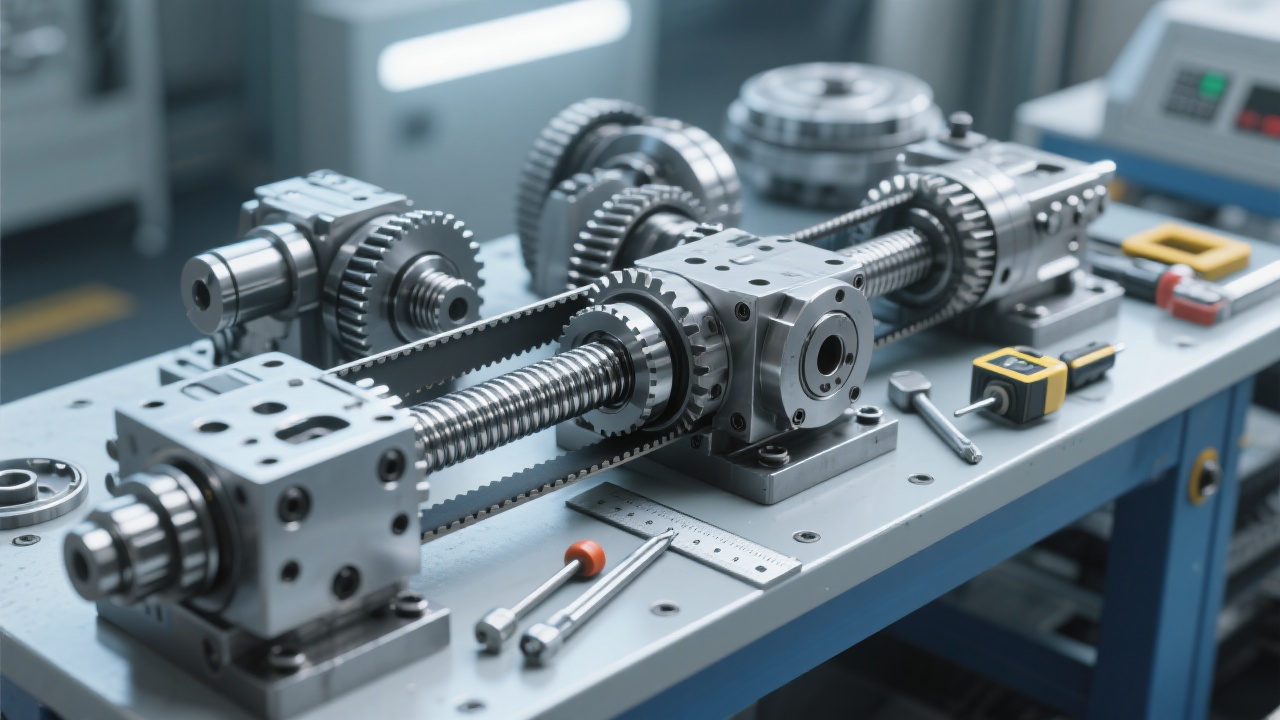

When it comes to guide rail types, there are linear guides and box - type guides. Linear guides offer high - speed movement and low friction, suitable for high - speed machining. Box - type guides, on the other hand, provide better rigidity and stability, ideal for heavy - duty machining. The choice depends on your specific production requirements.

Spindle power is also crucial. For gray cast iron and ductile cast iron, a spindle power of 11 - 15kW is usually sufficient for general machining. However, for large - scale or high - speed machining, a higher spindle power may be needed.

Gray cast iron and ductile cast iron have different cutting characteristics. Gray cast iron has good machinability but is prone to chipping. Ductile cast iron, on the other hand, has higher strength and toughness, requiring more powerful cutting tools and machines. For gray cast iron, a machine with a relatively lower spindle power but higher cutting speed may be suitable. For ductile cast iron, a machine with higher spindle power and better rigidity is recommended. It's important to emphasize process adaptability rather than simply piling up hardware.

To avoid being misled by parameters, it's essential to conduct trial cutting tests. Before making a purchase, you can ask the manufacturer to perform a trial cut on a sample workpiece. Observe the cutting quality, such as surface roughness, dimensional accuracy, and chip formation. A good trial cut should achieve a surface roughness of Ra 3.2μm or better. You can also check the machine's stability during the trial cut. If the machine vibrates significantly, it may not be suitable for high - precision production.

We've prepared a pre - trial - cut checklist and a pitfall - avoidance guide for you. The checklist includes items such as machine appearance inspection, electrical system check, and lubrication system inspection. The pitfall - avoidance guide helps you identify common problems in machine selection, such as false parameter claims and inappropriate after - sales service.

Kaibo CNC has 25 years of experience in the industry, focusing on every machine. By choosing Kaibo CNC's DC1113, you're choosing a reliable and high - quality machine. Don't miss this opportunity to build a stable and efficient iron mold production line. Click the button below to learn more!