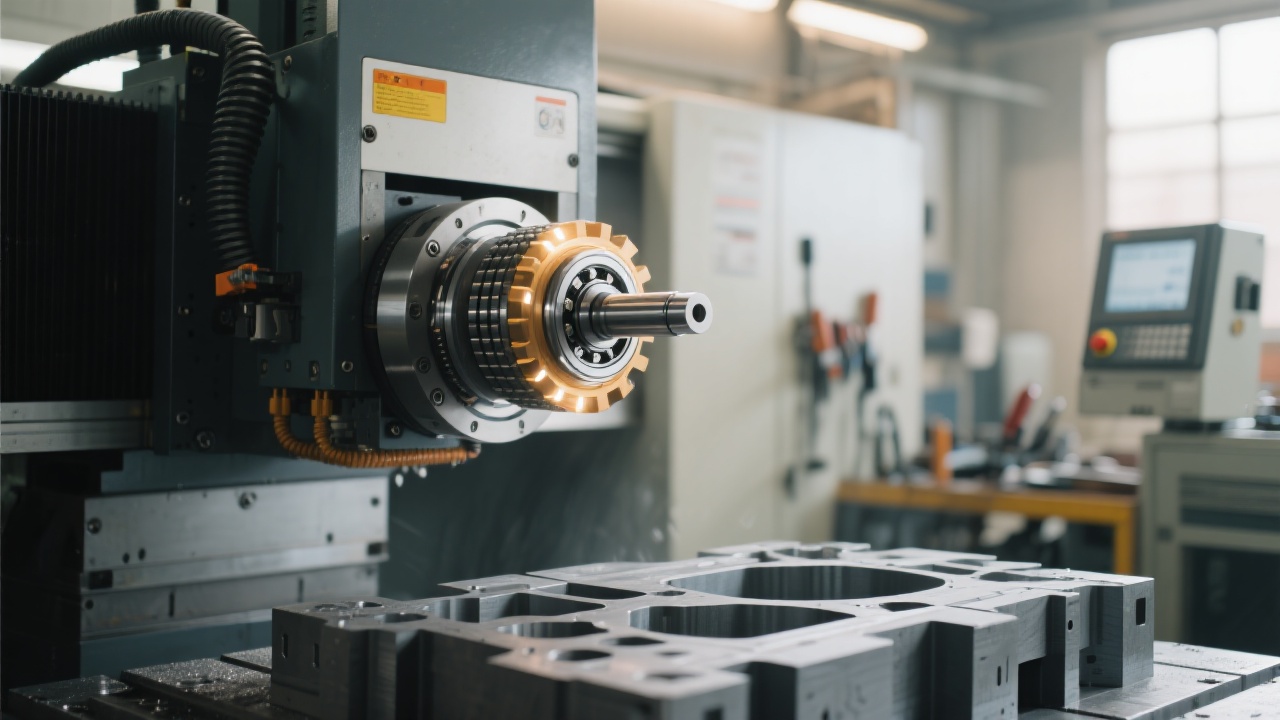

When manufacturing automotive components, grinding down production time without compromising quality is paramount. One of the most effective levers is optimizing your CNC machining setup — particularly for heavy-duty rough machining. By focusing on machine rigidity, control system stability, and dynamic power delivery, you can significantly enhance machining cycle times and overall throughput. Let’s dive into how leveraging the FH1890L vertical machining center paired with precise parameter tuning and specialized attachments can transform your rough machining process.

The FH1890L is engineered with a robust structural design that minimizes vibration and maximizes cutting stability. Its heavy cast iron frame supports the massive forces in rough machining automotive parts, such as engine blocks and transmission housings. The optimized bed and column layout ensure consistent stiffness even at high feed rates, which directly translates into improved surface finishes at faster cycle times.

Technical insight: With a spindle power rating of up to 22 kW and torque exceeding 300 Nm, the FH1890L maintains cutting integrity even under aggressive chip loads, allowing for feed rates 15-20% higher than less rigid machines.

Stability and control are critical when pushing the limits of rough machining. The Mitsubishi CNC controller integrated into the FH1890L provides real-time adaptive feed and acceleration optimization, reducing cycle times through efficient pathing and dynamic load compensation. This results in smoother acceleration profiles and decreased non-cutting times.

Recommended settings: Utilize the controller’s advanced macros to set ramp feed-in and ramping feed-out parameters, optimizing tool engagement angle to minimize shock loads.

Machine responsiveness depends on drivetrain components—high-default torque spindles combined with precise servo motors ensure the power train reacts instantly to command inputs. For rough machining, maintaining stable torque under load ensures the cutting tool doesn’t stall or chatter.

For instance, increasing feed rate from 0.15 mm/tooth to 0.2 mm/tooth while maintaining spindle speed near 3,600 RPM can shorten machining time by up to 18%, provided tool and workpiece rigidity are assured.

| Parameter | Recommended Range | Effect on Cycle Time |

|---|---|---|

| Cutting Speed (Surface m/min) | 150 - 220 | Increases material removal rate, reduces cycle |

| Feed Rate (mm/min) | 2,500 - 3,200 | Optimizes chip load without tool deflection |

| Depth of Cut (mm) | 4 - 6 (depending on tool & material) | Balances volume removed per pass and stability |

| Tool Selection | Carbide inserts with coated grade for hardness | Improves wear resistance and cutting precision |

Rough machining automotive parts often involves intricate features and undercuts difficult to reach with a fixed spindle orientation. Using accessories such as right-angle heads and universal joint heads extends cutting access, enabling multi-axis machining that dramatically reduces setups and repositioning time.

In practice, applying a right-angle head on the FH1890L reduced cycle time for gearbox housing rough cuts by approximately 12%, by eliminating multiple clamping operations.

A leading automotive parts manufacturer integrating the FH1890L with optimized parameters and right-angle tooling reported the following improvements:

“Configuring our FH1890L with the recommended machining parameters and adopting the multi-functional right-angle attachment was a game changer. Not only did cycle times drastically drop, but part quality improved, aligning with our rigorous automotive standards.” – Manufacturing VP, Client A

Ready to slash your automotive parts rough machining cycle times with expert CNC configurations? Discover How FH1890L Enhances Your Production Efficiency Today