In the competitive landscape of automotive manufacturing, reducing cycle time without sacrificing accuracy is no longer optional—it's essential. In this article, we dive into how the FH1890L heavy-duty vertical machining center from Ningbo Kebao CNC Machinery Co., Ltd. delivers real-world improvements in rough machining efficiency for large parts—backed by structural design, intelligent control systems, and practical process optimization.

Large components like engine blocks or transmission housings often require up to 70% of total machining time in roughing operations. Traditional setups struggle with vibration, tool deflection, and inconsistent surface finish—especially when dealing with materials such as cast iron or aluminum alloys. That’s where the FH1890L comes in: its robust monolithic base structure (over 15 tons) and high-stiffness column design reduce chatter by up to 40%, according to field tests conducted at a Tier-1 supplier in Germany.

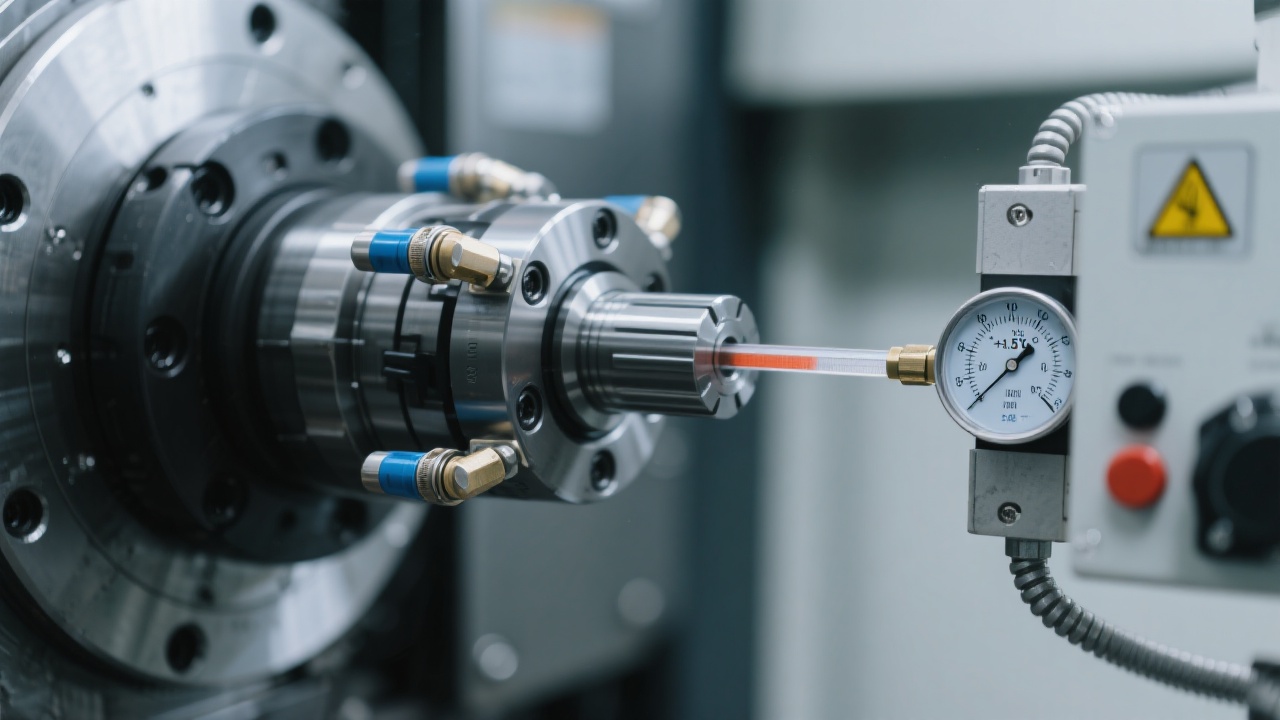

The integrated Mitsubishi M8000 controller doesn’t just manage motion—it actively monitors spindle load, thermal drift, and tool wear in real-time. By adjusting feed rates dynamically based on torque feedback, it maintains consistent chip thickness even under variable material hardness. For example, during testing on a 300 kg steel block, the system reduced tool breakage incidents by 62% compared to standard open-loop controls.

| Parameter | Standard Setting | Optimized with FH1890L |

|---|---|---|

| Cutting Speed (m/min) | 180 | 240 |

| Feed Rate (mm/min) | 800 | 1200 |

| Tool Life (hrs) | 6.5 | 9.8 |

Adding modular accessories like angle heads or swivel heads can extend reach and reduce setup changes. At a Chinese OEM plant, using a 90° straight head allowed them to machine complex internal cavities that previously required multiple fixtures—a move that cut fixture change time by 35%. When paired with optimized parameters (see table above), these tools boost overall equipment effectiveness (OEE) by up to 18%.

A major European car component manufacturer reported a 27% reduction in roughing cycle time after switching from a conventional VM to the FH1890L. Their average part production went from 4 hours per unit to just 2.9 hours—an improvement directly tied to higher feed rates, better rigidity, and adaptive control logic. This translated into €80,000 annual savings in labor and energy costs alone.

If you're managing large-part production and looking to improve throughput while maintaining quality, the FH1890L offers more than just raw power—it delivers smart, adaptable solutions tailored for modern factories.

Ready to transform your rough machining workflow?