In the realm of graphite processing, achieving high - precision, stable, and repeatable machining is a long - standing challenge. The culprit behind many of these issues is dust pollution, which can significantly impact the efficiency and quality of the machining process. This article delves into the problems caused by graphite dust and presents an innovative solution: the wet graphite machining center DC6060G.

Graphite dust is a persistent problem in graphite machining. It has a tendency to adhere to the surface of workpieces and infiltrate critical components such as guide rails, lead screws, and electrical systems. When dust accumulates on the workpiece surface, it can cause unevenness, leading to inaccuracies in subsequent machining operations. Meanwhile, when it gets into the guide rails and lead screws, it can increase friction, resulting in precision drift. In electrical systems, dust can cause short - circuits and other malfunctions, ultimately leading to equipment failure.

The impact of dust on machining is multi - faceted. Firstly, dust can cause an increase in positioning errors. As dust adheres to the positioning elements, the actual position of the workpiece may deviate from the set position, making it difficult to achieve the desired accuracy. For example, in high - precision graphite machining, even a small positioning error can lead to significant quality issues.

Secondly, dust has a negative impact on tool life. When cutting tools come into contact with dust - laden workpieces, the abrasion on the tools increases significantly. This not only shortens the tool life but also affects the surface finish of the workpiece, reducing the overall quality of the machining process.

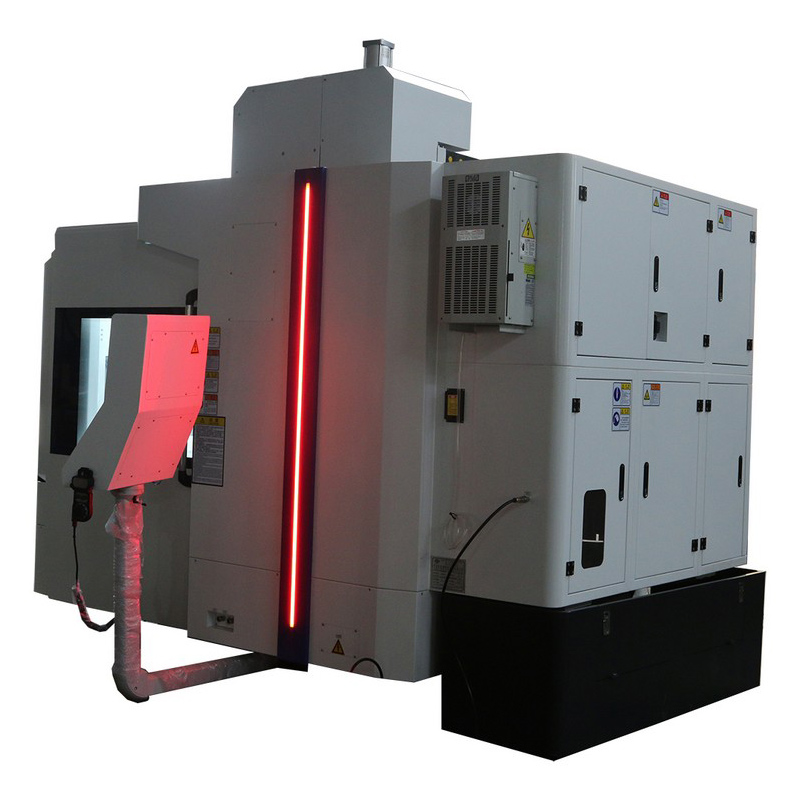

The wet graphite machining center DC6060G offers a comprehensive solution to the dust problem. It combines a fully enclosed cover design with a wet flushing system.

The fully enclosed cover acts as a physical barrier, preventing dust from entering the key components of the machine. This design effectively isolates the machining area from the external environment, reducing the chance of dust intrusion. The wet flushing system, on the other hand, works in real - time to clean the residues generated during the machining process. It uses a special cleaning fluid to wash away the dust and chips, ensuring a clean machining environment.

Actual test data has shown that the DC6060G is highly effective in improving machining repeatability. With the combination of the fully enclosed cover and the wet flushing system, the machine can achieve a repeat accuracy of ±0.01mm. This is a significant improvement compared to traditional graphite machining methods, where the repeat accuracy is often much lower.

For example, in a series of tests, the traditional machining method had a positioning error of up to ±0.05mm, while the DC6060G maintained a stable positioning accuracy within ±0.01mm. This not only improves the quality of the machined products but also reduces the scrap rate, increasing overall production efficiency.

The wet graphite machining center DC6060G is particularly suitable for high - end manufacturing fields such as semiconductors and power batteries. In these industries, the requirements for cleanliness and consistency are extremely high. For semiconductor manufacturing, even the slightest dust particle can cause defects in the chips, leading to significant losses. Similarly, in power battery production, the consistency of graphite components is crucial for battery performance.

The DC6060G can meet these strict requirements by providing a clean and stable machining environment. It helps these industries achieve high - consistency mass production, which is the key to maintaining competitiveness in the market.

If you are looking for an efficient dust control solution in graphite machining or want to obtain a case white paper, click here to learn more. Our wet graphite machining center DC6060G is your reliable partner for achieving efficient, reliable, and mass - producible precision graphite machining.