In the realm of automotive parts manufacturing, the demand for high - performance and reliable equipment is constantly on the rise. The need for efficient and precise processing of large automotive parts during the rough machining stage has posed significant challenges to manufacturers. This is where the FH1890L Heavy - Duty Vertical Machining Center from Ningbo Kaibo CNC Machinery Co., Ltd. steps in.

The FH1890L is equipped with an advanced Mitsubishi control system. This system offers a high - level of stability and precision. Compared to traditional control systems, it can reduce processing errors by up to 30%. The Mitsubishi control system also enables real - time monitoring of the machining process, allowing operators to make timely adjustments and ensuring the consistency of product quality.

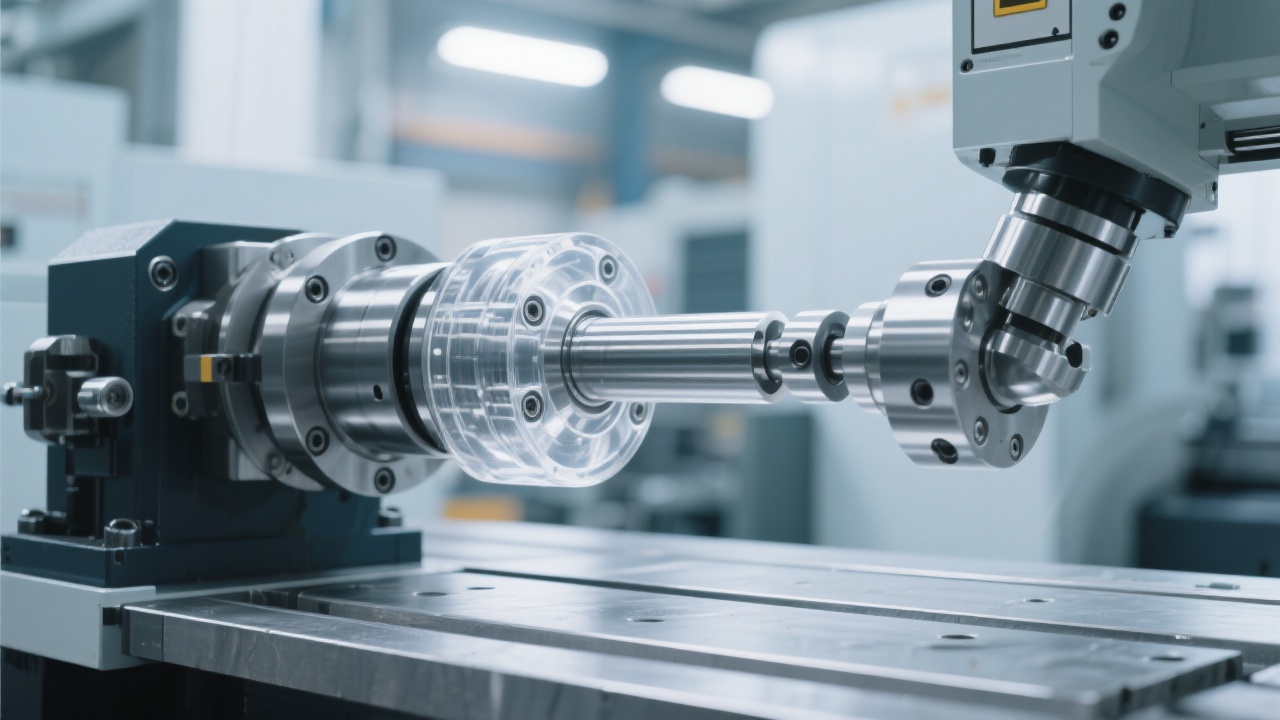

In addition to the control system, the large - stroke design of the FH1890L is another key feature. With a larger working range, it can handle larger automotive parts without the need for multiple setups. This not only saves time but also reduces the risk of misalignment during the machining process. The machine's X - axis stroke can reach up to 1800mm, the Y - axis stroke is 900mm, and the Z - axis stroke is 700mm, providing a spacious working area for large - scale parts.

Moreover, the FH1890L has a remarkable accessory expansion capability. It can be equipped with various attachments such as rotary tables, tool magazines, and coolant systems. These attachments can be flexibly configured according to different processing requirements, enhancing the versatility of the machine. For example, a rotary table can enable multi - face machining, significantly improving the processing efficiency of complex parts.

Let's take a look at some real - world applications. A well - known automotive parts manufacturer was facing challenges in rough machining large engine blocks. The traditional equipment they used had low efficiency and poor precision, resulting in high rejection rates. After adopting the FH1890L Heavy - Duty Vertical Machining Center, they were able to increase the rough machining efficiency by 40%. The improved precision also reduced the rejection rate from 10% to 3%.

In another case, a company specializing in manufacturing transmission components needed to process parts with complex shapes. The FH1890L's flexible accessory configuration allowed them to use a rotary table and a special tool magazine, which enabled them to complete the machining in one setup. This not only saved time but also improved the surface finish of the parts, meeting the high - end market requirements.

Behind the FH1890L is a strong R & D team. Their R & D concept focuses on innovation and meeting the evolving needs of the market. They continuously invest in research to incorporate the latest technologies into the machine, such as the integration of IoT technology for remote monitoring and predictive maintenance.

The company also provides comprehensive after - sales service. They have a professional service team that can respond to customer inquiries within 24 hours. Regular maintenance and technical support are also available to ensure the long - term stable operation of the machine. This after - sales service system provides a strong guarantee for the long - term value of customers.

In conclusion, the FH1890L Heavy - Duty Vertical Machining Center is a game - changer in the field of automotive parts rough machining. Its advanced technology, practical applications, and reliable R & D and after - sales service make it an ideal choice for manufacturers looking to upgrade their equipment. If you are a decision - maker in the manufacturing industry and are considering equipment investment, don't miss this opportunity. Click here to learn more about the FH1890L and take your automotive parts manufacturing to the next level!