In the fiercely competitive graphite electrode processing industry, staying ahead means embracing innovation and efficiency. The wet-flush graphite machining center DC6060G is not just another CNC milling machine — it is the industry’s premium choice that integrates cutting-edge technology with operational excellence.

Designed to withstand the unique challenges of graphite electrode manufacturing, the DC6060G transforms productivity and precision, allowing manufacturers to reduce costs and improve output quality. Miss it, and you will fall behind! This article dives deep into the unique features that set DC6060G apart and why global buyers should consider it an indispensable asset for their production lines.

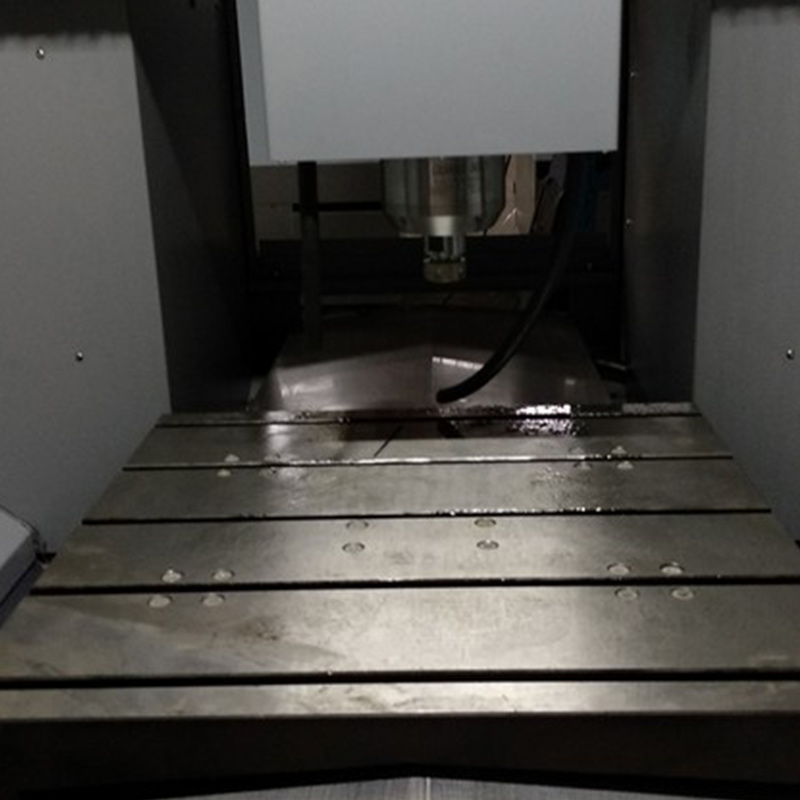

The DC6060G is tailor-made for graphite electrode processing, where controlling dust, ensuring machining accuracy, and maintaining operational stability are paramount. Unlike traditional dry processing centers prone to excessive dust and frequent maintenance, the DC6060G employs a fully enclosed sealing cover, effectively isolating dust particles and protecting both operators and equipment from contamination.

Complementing this, its wet flushing system continuously cools the machining zone with high-efficiency water flow, ensuring the graphite material does not overheat or crack while simultaneously washing away residual particles. This system supports a consistent milling environment, enabling the machine to sustain precision tolerances within ±0.01mm, which is critical for high-performance electrodes.

The DC6060G surpasses industry standards with its water curtain dust removal device, which traps airborne graphite dust at the source. Combined with a multi-shared water tank design and an advanced circulating filtration system, it guarantees clean water recycling, reduces resource consumption by up to 40%, and significantly lowers maintenance downtime.

| Feature | DC6060G | Typical Dry Machining Center |

|---|---|---|

| Dust Control | Fully sealed + water curtain removal | Open spindle area, limited extraction |

| Water Consumption | Recycled with filtration (up to 40% saving) | Constant fresh water usage |

| Operational Precision | ±0.01 mm achievable | ±0.05 mm or more |

| Maintenance Frequency | Reduced by 30% | High, due to dust and wear |

Consider a leading graphite electrode manufacturer in Japan: after integrating the DC6060G into their production line, they reported a 25% increase in throughput with 20% lower operational costs within six months. The fully sealed system drastically improved workplace safety by virtually eliminating dust exposure, a constant challenge in their previous setup.

Another case from a Chinese graphite electrode producer shows that the multi-shared water tank and circulating filter system cut water consumption by nearly half, aligning with increasingly strict environmental regulations while simultaneously boosting milling precision to unmatched levels.

Operators who have switched to the DC6060G praise its intuitive CNC controls and consistent machining quality. “The machine’s stability means we can run longer shifts without downtime,” commented one senior technician. “Plus, the near-zero dust environment has transformed our factory air quality, making it safer and more pleasant.” Such feedback reflects the machine’s synergy between human-machine ergonomics and engineering excellence.

Globally, graphite electrode demand is projected to grow steadily due to booming steel production and electric arc furnace adoption. As environmental and precision requirements tighten, manufacturers need equipment that not only meets current needs but also anticipates future challenges. The DC6060G’s wet processing technology, comprehensive dust control, and resource-efficient design position it uniquely as the preferred solution for smart factories aiming to lead in innovation and sustainability.

In conclusion, the wet-flush graphite machining center DC6060G is the industry’s elite choice for graphite electrode processing. Its advanced sealing, wet flushing, and filtration designs deliver unparalleled precision, operational cost savings, and a healthier production environment. Don’t miss out — adopting the DC6060G today means securing your company’s competitive edge tomorrow!