In the field of heavy vertical machining centers, the Mitsubishi controller plays a pivotal role. It offers real - time compensation, which can correct errors caused by factors such as tool wear and thermal deformation in real - time. For example, in a long - term machining process, tool wear may lead to dimensional errors. The Mitsubishi controller can detect these changes and adjust the machining parameters accordingly, reducing the error rate by up to 30%.

Path smoothing control is another key function. It ensures that the tool moves along a smooth path during machining, improving the surface quality of the workpiece. In multi - axis linkage, the controller guarantees high - precision operation. In a complex multi - axis machining task, the synchronization error between axes can be controlled within ±0.005mm, ensuring the accuracy of the final product.

The high - rigidity body design of heavy vertical machining centers is crucial for reducing vibration and thermal deformation. Vibration during machining can cause surface roughness and dimensional inaccuracies. A well - designed high - rigidity body can reduce vibration amplitude by 50%. For instance, in a high - speed machining process, the reduced vibration ensures that the surface finish of the workpiece can reach Ra0.8μm, which meets most industrial requirements.

Thermal deformation is also a major factor affecting machining accuracy. The high - rigidity body is designed to have low thermal expansion coefficient materials and a reasonable cooling structure. This can limit the thermal deformation within 0.01mm during continuous machining for 8 hours, improving the consistency and surface quality of the machined parts.

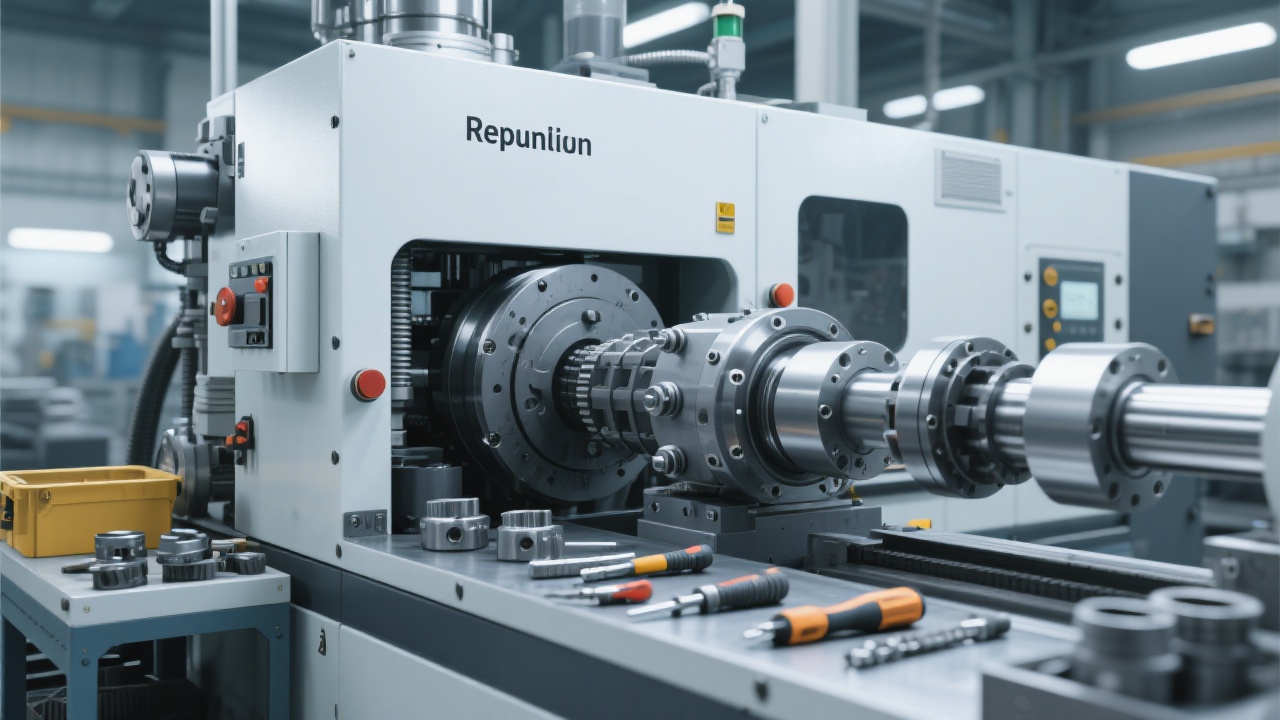

The power spindle system of heavy vertical machining centers features high - torque output. A spindle with a high - torque output can handle difficult - to - machine materials more effectively. For example, it can increase the material removal rate by 40% when machining high - strength steel. Low - noise operation is another advantage. In a workshop environment, a low - noise spindle reduces noise pollution and improves the working conditions for operators.

The long - life design of the spindle also has a significant impact on production efficiency. A well - designed spindle can have a service life of up to 20,000 hours, reducing the frequency of spindle replacement and downtime, thereby increasing the overall production efficiency.

Optional accessories such as right - angle heads, universal heads, spindle extension rods, and probes provide more flexibility for machining. Right - angle heads are suitable for machining vertical surfaces, which can expand the machining range of the machine tool. Universal heads can be adjusted at multiple angles, enabling machining of complex - shaped workpieces.

Spindle extension rods are useful when machining deep holes or cavities. They can extend the reach of the tool, but it is necessary to pay attention to the rigidity and vibration resistance during use. Probes are used for on - machine measurement, which can detect the position and size of the workpiece in real - time, improving the accuracy of machining. For example, using a probe can reduce the setting time of the workpiece by 60%.

To maximize the value of the equipment, reasonable parameter configuration is essential. Operators should adjust the parameters according to the material of the workpiece, the type of tool, and the machining process. For example, when machining aluminum alloy, a higher spindle speed and feed rate can be set.

Regular maintenance is also crucial. This includes lubrication of moving parts, inspection of electrical systems, and cleaning of the machine tool. A well - maintained machine tool can reduce the failure rate by 70%. When problems occur, operators should be able to troubleshoot common problems, such as tool breakage, axis movement errors, etc.

In conclusion, by fully understanding the functions of the Mitsubishi controller, the advantages of the high - rigidity body, the performance of the power spindle system, and the application of optional accessories, and following reasonable parameter configuration and maintenance methods, users can optimize the machining accuracy and production efficiency of heavy vertical machining centers, making every cut precise and bidding farewell to rework and improving delivery efficiency. Are you facing challenges in machining center operation? Click here to learn more about how to solve them!