In the automotive components and heavy machinery industries, one recurring challenge is the low efficiency in rough machining of large parts. After years of hands-on experience with global manufacturers, it's evident that the root causes lie often in suboptimal machine tool rigidity, insufficient power delivery, and inadequate parameter optimization. This article focuses on how the FH1890L large travel heavy-duty vertical machining center, leveraging its robust structural rigidity, powerful spindle system, and advanced Mitsubishi CNC controller, can significantly elevate rough machining efficiency for large workpieces.

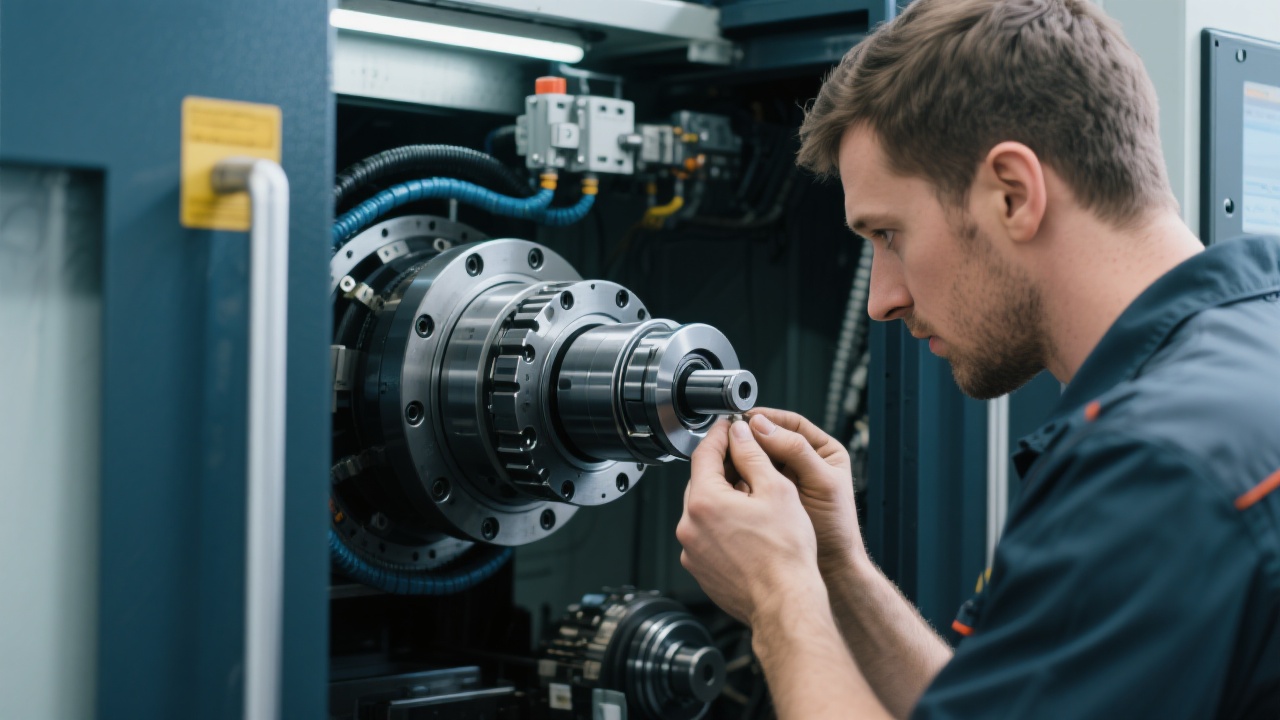

The FH1890L's heavy casting bed is engineered using advanced metallurgy to maximize vibration damping and static rigidity. Its guideways feature high-precision linear roller bearings with a positioning accuracy within 0.005 mm, ensuring minimal deflection under heavy cutting forces. The spindle unit delivers a peak power of 45 kW with a torque of 350 Nm, providing strong and consistent cutting force output. This combination reduces chatter and tool wear, directly impacting surface finish uniformity and increasing feed rates.

In a case with an automotive wheel hub manufacturer, upgrading to FH1890L resulted in a 30% reduction in single-piece rough machining time, attributable primarily to enhanced machine stability and power delivery during heavy cuts.

Optimizing cutting parameters such as spindle speed, feed rate, depth of cut, and tool selection is crucial. For rough machining large automotive parts, typical parameters range from 500 to 800 RPM spindle speed, 1200 to 1800 mm/min feed rate, and 6 to 12 mm depth of cut, depending on material hardness and tool geometry.

Using high-performance carbide insert tools tailored to the alloy being machined minimizes tool wear and maximizes chip evacuation. Matching these parameters dynamically via the Mitsubishi CNC controller’s adaptive feed functionality leads to optimized cutting conditions and reduces non-cutting time.

| Parameter | Typical Value Range | Application Notes |

|---|---|---|

| Spindle Speed (RPM) | 500 - 800 | Adjust to material and tool balance to prevent excessive wear |

| Feed Rate (mm/min) | 1200 - 1800 | Higher feed for softer alloys, moderated for tougher steels |

| Depth of Cut (mm) | 6 - 12 | Dependent on machine rigidity and tool stability |

| Tool Type | Carbide Inserts | Optimized for aluminum, steel, or cast iron variants |

The FH1890L supports multi-functional attachments such as right-angle heads and universal heads, which broaden its capability in machining complex surfaces, deep cavities, and inclined planes often found in automotive parts.

Using a right-angle head reduces tool overhang, increasing rigidity and enabling higher feed rates on side faces. The universal head allows machining at variable angles without reclamping, effectively minimizing setup times and improving overall process flow efficiency.

For example, one automotive supplier integrated the universal head in rough machining of wheel hubs with deep recesses, cutting total machining time by 22% compared to fixed-head configurations.

A leading wheel hub manufacturer switched to FH1890L centers to overcome rough machining bottlenecks. Post-implementation, the single-piece processing cycle time dropped by over 30%. Additionally, tool life extended by 15%, and surface roughness consistency improved by 20%, reducing post-machining rework.

These improvements collectively enhanced production throughput, lowered operational costs, and strengthened on-time delivery performance, underscoring the tangible value of combining heavy-duty machine design with process parameter and accessory optimization.

Improving rough machining efficiency for large parts demands an integrated approach—starting from machine tool structural design and power systems, through cutting parameter fine-tuning, to application of multifunctional attachments. The FH1890L heavy-duty vertical machining center exemplifies this synergy, delivering measurable cycle time reductions and quality improvements for automotive component manufacturers.

If your machining operations face similar challenges in reducing cycle times and improving roughing quality on large workpieces, exploring FH1890L’s capabilities could be pivotal.