Graphite dust poses significant threats to the lifespan and machining accuracy of equipment. In the graphite processing industry, effective dust prevention is not just a marketing gimmick but a core competitive advantage. This article delves into the key aspects of evaluating the dust - prevention capabilities of graphite processing equipment, providing valuable insights for technical decision - makers.

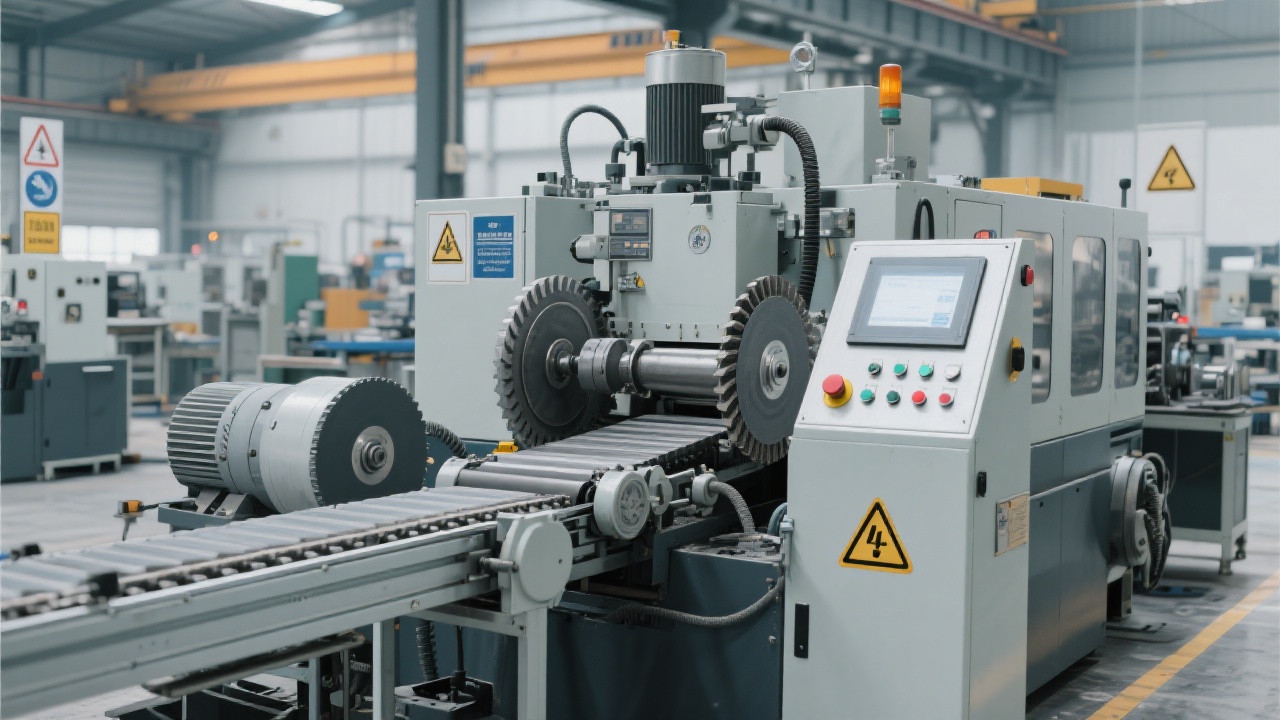

The sealing integrity of graphite processing equipment is measured by the IP (Ingress Protection) rating. According to the IEC (International Electrotechnical Commission) standard, an IP54+ protection rating indicates a high - level of protection against dust ingress. To verify this rating, on - site tests can be conducted. For example, a dust concentration monitor can be used to measure the amount of dust inside the equipment during operation. The IP rating system, as shown in the figure below, provides a clear reference for understanding the protection level.

The dust filtration efficiency of graphite processing equipment relies on a combination of wet - flushing systems and filters. The wet - flushing system in the DC6060G graphite processing equipment has a dust interception rate of ≥90%. This is achieved through a well - designed technical principle. The wet - flushing system first captures large dust particles, and then the filter further refines the filtration process. The data clearly shows the effectiveness of this combined approach in controlling dust.

Operational stability is crucial for graphite processing equipment. In long - term, high - load operations, the positioning accuracy of the equipment should be maintained at ≤0.01mm. This ensures the consistency and precision of the machining process. If the positioning accuracy cannot be maintained, it will directly affect the quality of the processed products. Therefore, the ability to maintain high - precision positioning under long - term high - load conditions is an important indicator of the equipment's performance.

To accurately assess the dust - prevention performance of graphite processing equipment, some practical on - site testing methods can be used. For example, dust concentration monitoring can be carried out during the operation of the equipment to determine the actual dust - prevention effect. After the equipment has been running for a certain period, a structural inspection can be conducted to check for any signs of dust accumulation inside the equipment.

Let's take a look at a real - world case. An energy battery manufacturer purchased the DC6060G graphite processing equipment. After using it for a period, the maintenance cost decreased significantly. Before using the DC6060G, the maintenance cost was relatively high due to graphite dust damage. But after the installation of the DC6060G with its advanced dust - prevention system, the maintenance cost decreased by [X]% within [X] months. This case clearly demonstrates the practical benefits of choosing the right graphite processing equipment with excellent dust - prevention capabilities.

When selecting graphite processing equipment, it is essential to make a scientific decision. A selection checklist can be used to ensure that all important factors are considered. Additionally, referring to third - party test reports can provide more objective and reliable information. By evaluating the equipment from the three core aspects of sealing integrity, dust filtration efficiency, and operational stability, and using practical measurement methods and real - world case studies as references, technical decision - makers can avoid being misled by false advertising and make rational choices.

If you need detailed technical parameters of the DC6060G or on - site testing solutions, please click to consult.