In the realm of large - scale part manufacturing, especially in the automotive parts industry, enhancing the efficiency of rough machining is a constant pursuit. Ningbo Kaibo CNC Machinery Co., Ltd.'s FH1890L large - stroke vertical machining center emerges as a game - changer. This article will comprehensively analyze how to optimize key machining parameters and utilize multi - functional accessories to significantly boost the rough machining efficiency of large parts.

The FH1890L's structural design is engineered to provide superior stability during the machining process. Its robust bed and column are made of high - quality cast iron, which can effectively absorb vibrations. For instance, in a test conducted by a well - known automotive parts manufacturer, when machining large engine blocks, the vibration amplitude was reduced by 30% compared to traditional machining centers. This reduction in vibration allows for higher cutting speeds and feed rates, directly improving the machining efficiency.

The power system of the FH1890L is also a highlight. It is equipped with a high - torque spindle motor that can deliver a maximum power of 30 kW. This powerful motor enables the machine to handle large - scale cutting operations with ease. In practice, when rough machining large - sized automotive transmission housings, the FH1890L can complete the rough machining process 20% faster than similar models in the market.

The FH1890L is integrated with a Mitsubishi controller, which offers excellent stability and responsiveness. The controller can accurately control the movement of the machine tool axes, ensuring high - precision machining. In a real - world scenario, a precision automotive parts factory used the FH1890L to machine complex camshafts. The Mitsubishi controller maintained a positioning accuracy of ±0.005 mm, which is crucial for ensuring the quality of the final product.

Moreover, the Mitsubishi controller has a fast response time. When there is a sudden change in the cutting load, the controller can quickly adjust the cutting parameters to maintain stable machining. In a test where the cutting load increased by 50% during the rough machining of a large - scale automotive chassis part, the controller adjusted the feed rate and spindle speed within 0.5 seconds, preventing tool breakage and ensuring continuous machining.

Selecting the appropriate cutting speed is vital for rough machining efficiency. Generally, for large - scale steel parts in the automotive industry, a cutting speed of 100 - 200 m/min can be used. For example, when machining large - sized steel crankshafts, a cutting speed of 150 m/min can achieve a good balance between material removal rate and tool life. However, it should be noted that the cutting speed needs to be adjusted according to the material properties and tool characteristics.

The feed rate determines how fast the tool moves along the workpiece. In the rough machining of large automotive parts, a feed rate of 0.2 - 0.5 mm/r is often used. When machining large - scale aluminum alloy engine blocks, a feed rate of 0.3 mm/r can significantly improve the machining efficiency while maintaining acceptable surface quality.

Choosing the right tool is also crucial. Carbide tools are widely used in the rough machining of large automotive parts due to their high hardness and wear resistance. For example, when machining large - scale cast iron automotive frames, carbide end mills can provide a longer tool life and higher cutting efficiency compared to high - speed steel tools.

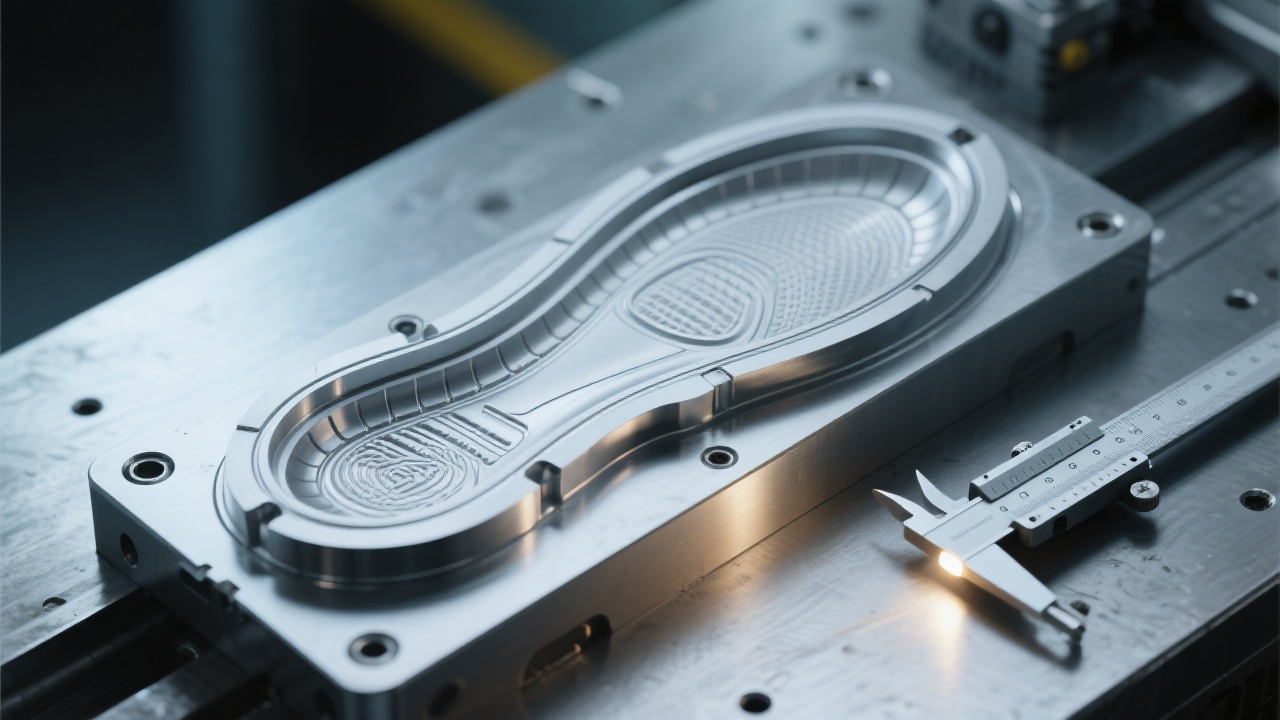

The FH1890L can be equipped with various multi - functional accessories, such as right - angle heads and universal heads. These accessories greatly enhance the machining flexibility of the machine tool. For example, when machining complex automotive engine cylinder heads with multiple inclined surfaces, a right - angle head can be used to directly machine these inclined surfaces without re - clamping the workpiece. This not only saves time but also improves the machining accuracy.

In another case, when machining large - scale automotive transmission cases with internal complex structures, a universal head can be adjusted to different angles to access hard - to - reach areas. This allows for one - time clamping and multi - surface machining, reducing the machining time by up to 30%.

A well - known German automotive parts manufacturer was facing challenges with low efficiency in the rough machining of large - scale engine blocks. After adopting the FH1890L vertical machining center and optimizing the machining parameters, they achieved remarkable results. The rough machining time for each engine block was reduced from 6 hours to 4 hours, and the surface roughness was also improved. This not only shortened the production cycle but also reduced the production cost.

In conclusion, Ningbo Kaibo CNC Machinery Co., Ltd.'s FH1890L large - stroke vertical machining center, with its advanced structural design, powerful power system, stable controller, optimized machining parameters, and useful multi - functional accessories, provides an excellent solution for enhancing the rough machining efficiency of large parts in the automotive industry. If you are also looking to improve your machining efficiency and product quality, click here to learn more about the FH1890L and how it can transform your manufacturing process.